How Our OEE Monitoring resolve your problems

- Run, Idle & Downtime

-

Problem: Unknown % of Machine Run,Idle, Downtime.

Problem: Unknown % of Machine Run,Idle, Downtime. -

Solution: Real-time machine

availability tracking and to analyse and prevent unplanned downtime.

Solution: Real-time machine

availability tracking and to analyse and prevent unplanned downtime. - Performance

-

Problem: Machines running below capacity which led to waste time and resources.

Problem: Machines running below capacity which led to waste time and resources. -

Solution: Performance tracking helps identify bottlenecks and optimize machine speed.

Solution: Performance tracking helps identify bottlenecks and optimize machine speed. - Quality

Problem: Problem:

Problem: Problem: -

Solution: Real-time machine

availability tracking and to analyse and prevent unplanned downtime.

Solution: Real-time machine

availability tracking and to analyse and prevent unplanned downtime. - Run, Idle & Downtime

-

Problem: Defective products result in waste and rework.

Problem: Defective products result in waste and rework. -

Solution: Continuous quality monitoring detects and find defects early, reducing scrap and rework.

Solution: Continuous quality monitoring detects and find defects early, reducing scrap and rework. - Efficient Decision-Making

-

Problem: Lack of real-time and historic data leads to wrong assumptions and poor decision-making.

Problem: Lack of real-time and historic data leads to wrong assumptions and poor decision-making. -

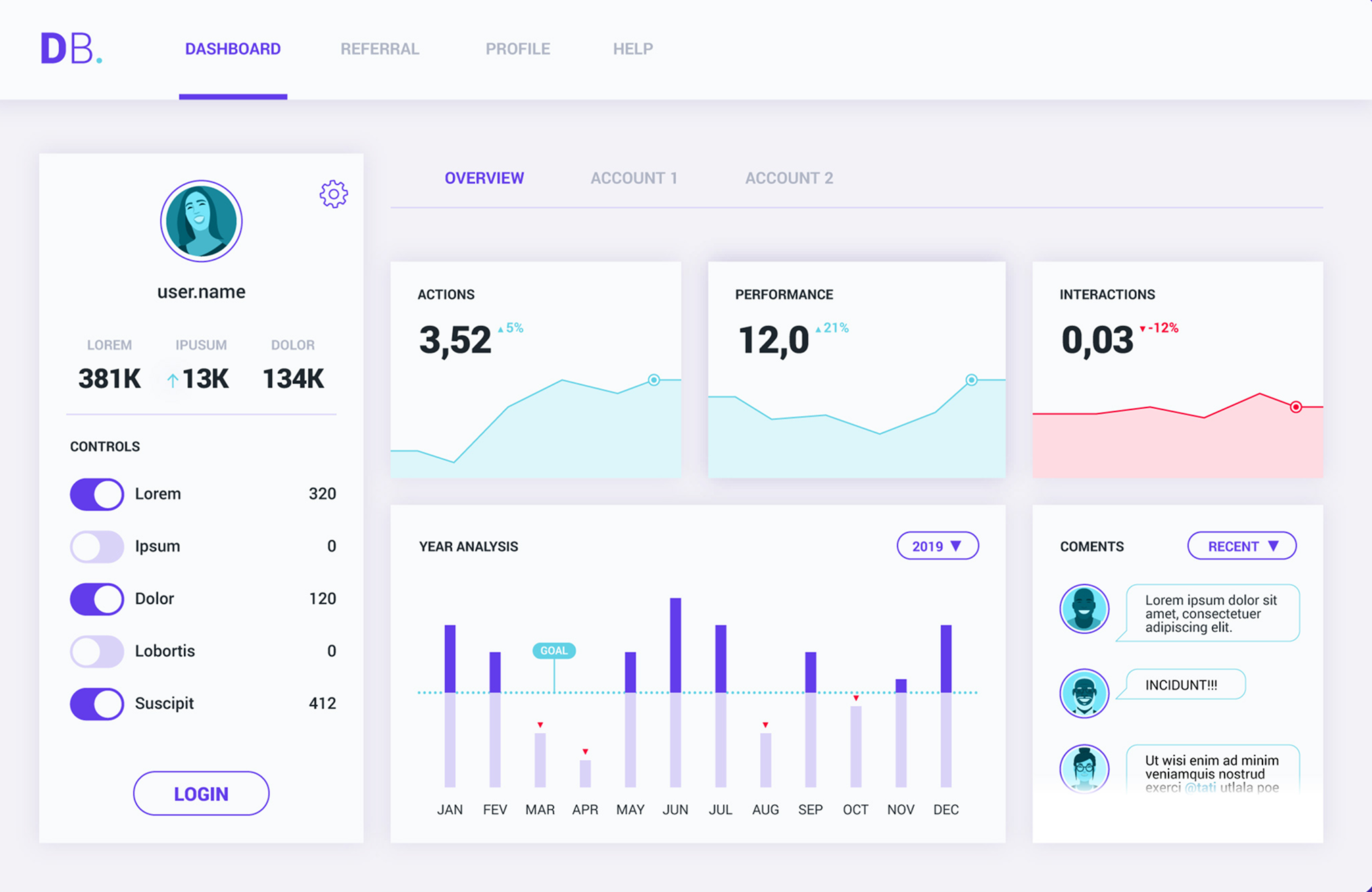

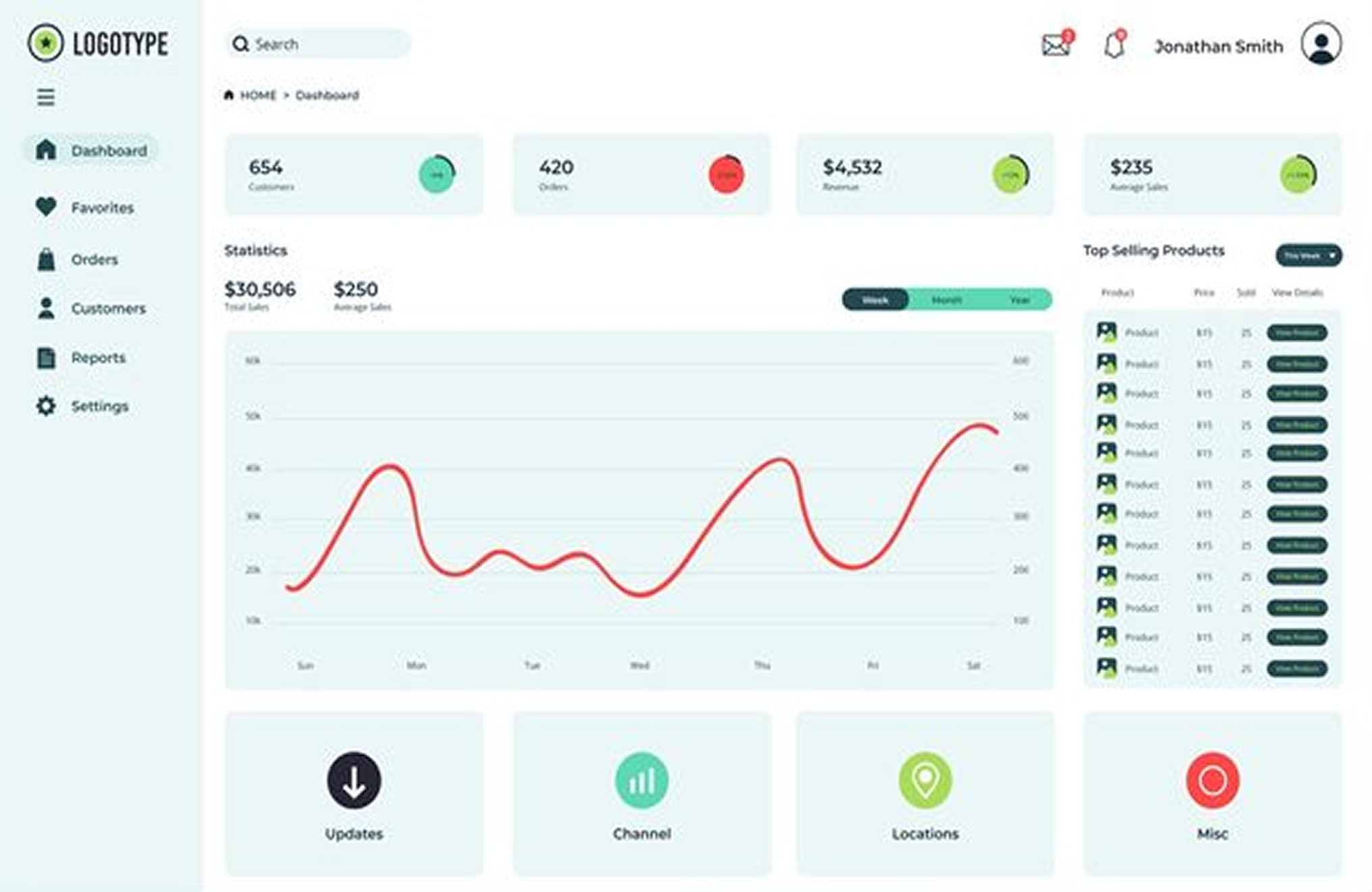

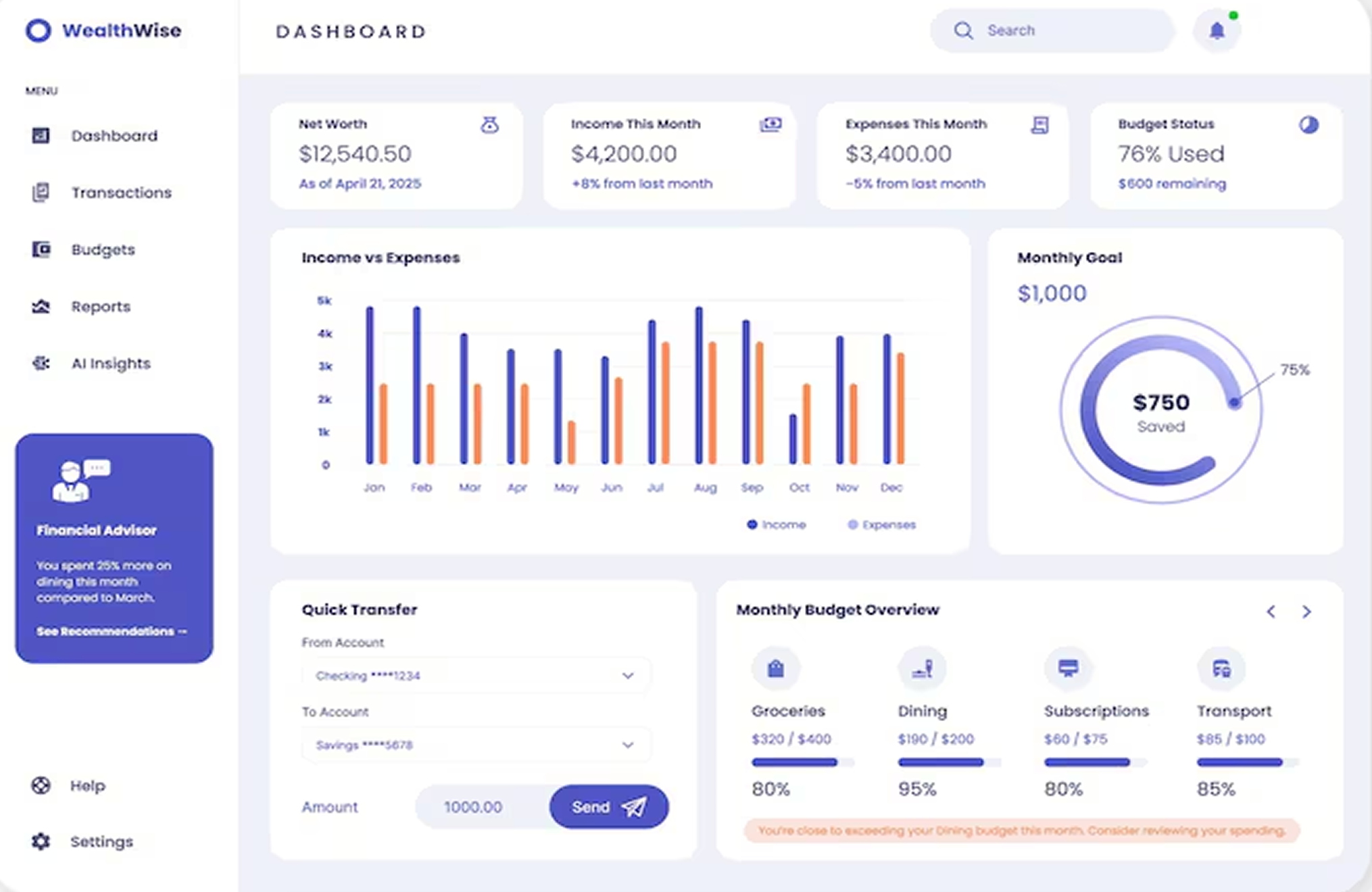

Solution: OEE data dashboards provide actionable insights for better decisions.

Solution: OEE data dashboards provide actionable insights for better decisions.

How Our OEE Monitoring resolve your problems

Machine Downtime Monitoring is the systematic tracking, classification and analysis of machine stoppages—planned or unplanned.

By leveraging smart sensors, connectivity to PLCs, IIoT gateways and our cloud/edge platform, MICROCIL logs downtime events in real time, captures contextual data (machine, shift, operator, reason code) and visualises this through dashboards built for actionable decisions.

With our solution you get insight such as:

- When a machine stopped and how long the stoppage lasted

- Why the machine stopped (power failure, sensor fault, mechanical misalignment, operator setup, etc.)

- On which machine, during which shift and under which operator

- How this downtime impacts your productivity and OEE performance

- High level of precision turns downtime from invisible cost into visible opportunity.

AI Powered Machine Health Monitoring

Machine Health Monitoring continuously tracks machinery using sensors and AI/ML analytics to detect anomalies and predict failures. It helps reduce downtime, optimize maintenance, extend equipment life, improve safety, and lower costs. Overall machine health is represented as a percentage, where 100% means perfect condition, and lower values indicate the need for attention or immediate maintenance. AI-driven models also forecast future health trends, enabling proactive, data-driven decisions for smarter, more efficient industrial operations.

What is the Biggest LOSS in Machine Efficiency ? Unplanned Downtime

The largest contributor to lost Overall Equipment Efficiency (OEE) is typically Availability losses.

These occur when machines are scheduled to run but aren’t producing due to unplanned downtime , equipment breakdowns, changeovers, or micro stops . In many manufacturing plants, availability issues can account for 40–60% of total OEE loss , making it the most critical area for improvement.

Solution: Improving machine availability through real-time monitoring, predictive maintenance, and detailed downtime analysis delivers the fastest impact on OEE and overall production efficiency.