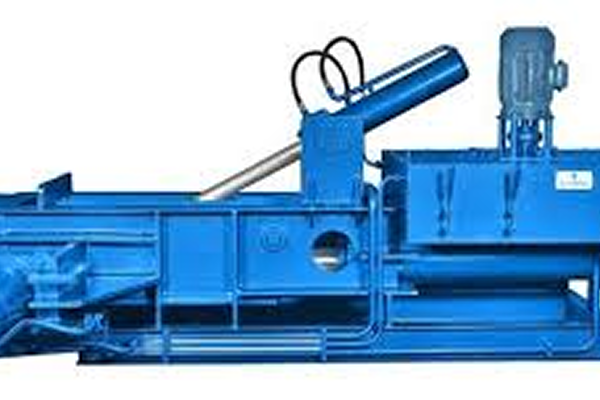

Continuous Scrap Baler

Description

The continuous balers built by Fabtex Engineering Works are designed to process metal scrap in a fully automated mode with continuous feeding, baling, and ejection. These balers are best suited for homogeneous metal scraps like UBCs (Used Beverage Cans), CRC, car body scrap, white goods, and other similar materials. Our hydraulic baling press features a triple-action mechanism, ensuring high-density bales and excellent results. With continuous feeding via magnet, grab crane, or conveyor, the scrap is compacted from three sides, maximizing efficiency and productivity.

Applications

- Aluminium sheets

- Plates

- Profiles

- Extrusions

- Window frames

- Panels

- Wheels

- Rims

- Car parts

- Radiators

- Used beverage cans (UBC)

- Aluminium containers

Technical Details

| Specification | FAB/CSB/DA/4 | FAB/CSB/DA/4A | FAB/CSB/TA/4 | FAB/CSB/TA/5 | FAB/CSB/TA/6 |

|---|---|---|---|---|---|

| Finished Bale Size (L × W × H) (inch) | 12 × 12 × 12 | 16 × 16 × 16 | Adjustable × 9.84 × 9.84 | Adjustable × 11.81 × 11.81 | Adjustable × 15.75 × 15.75 |

| Bale Weight Fe (lbs) | 88.18 | 154.32 | 152.11 | 273.373 | 581.95 |

| Bale Weight MS (lbs) | 110.23 | 176.37 | 171.96 | 310.852 | 663.59 |

| Bale Weight Al (lbs) | 66.14 | 110.23 | 61.72 | 97.0034 | 207.23 |

| Chamber Size (L × W × H) (inch) | 40 × 30 × 12 | 78 × 55 × 16 | 31.3 × 75.8 × 23.6 | 40.2 × 88.0 × 31.5 | 97.64 × 49.02 × 43.31 |

| Feed Opening (W × L) (inch) | 40 × 30 | 78 × 55 | 28.5 × 57.1 | 37.2 × 65.2 | 46.06 × 83.86 |

| Motor Power (hp) | 30 | 2 × 40 | 73.8 | 73.8 / 120.69 / 73.8 | 120.69 / 147.52 |

| Overall Size (L × W × H) (inch) | 90 × 75 × 40 | 170 × 135 × 80 | 228.3 × 179.1 × 118.1 | 260 × 208.3 × 147 | 316.34 × 250.39 × 181.10 |

Hydraulics & Add-On Features:

- Robust design

- Low maintenance requirements

- Easy operation with multi-display PLC-control panel

- Bale length and density can be changed as per customer’s needs

- After-sales on-demand service

- Automatic lubrication system

- Double Action system

- Triple Action system

Benefits:

- Low overall operating cost

- High productivity

- Super high-density bales

- Weight of the bales can be programmed and controlled

- Increased speed of movements

- Lower cycle times through the use of high-pressure pumps

- Low energy consumption

- Easy installation