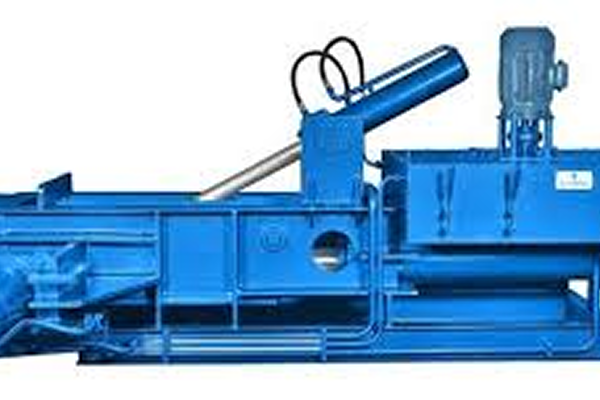

Triple Action Baling Press

Description

The compressing action of our Triple Action Metal Baler works on the scrap from three directions. This efficient and powerful triple compression scrap baling press machine compacts the metal scrap from the top, sideways, and longitudinally, resulting in highly dense and optimally compacted bales.

Fabtex Engineering Works manufactures Triple Action Balers for a wide range of recyclable metal scraps, including copper, iron, MS, aluminium, and other ferrous and non-ferrous metals. Our balers are ideal for customers looking to bale medium to large quantities of metal scrap, including stainless steel, aluminium, and copper scrap.

Our Triple Action Metal Baler is a heavy-duty, fully automatic machine, ensuring efficient and productive waste management solutions.

Applications

- Aluminium sheets

- Plates

- Profiles

- Extrusions

- Window frames

- Panels

- Wheels

- Rims

- Car parts

- Radiators

- Used beverage cans (UBC)

- Aluminium containers

Technical Details

| Specification | FAB/TSB - 85 | FAB/TSB – 85 | FAB/TSB - 120 | FAB/TSB - 150 | FAB/TSB – 150 | FAB/TSB - 180 |

|---|---|---|---|---|---|---|

| Bale Length (inch) | 8” | 10” | 12” | 12” | 15” | 14” |

| Bale Width (inch) | 8” | 10” | 12” | 12” | 15” | 14” |

| Bale Height (inch) | 8” – 10” | 10” – 12” | 5” – 8” | 5” – 8” | 10” – 20” | 8” – 10” |

| Bale Weight (lbs) | Up to 55.116 lbs | Up to 77.161 lbs | Up to 110.231 lbs | Up to 154.324 lbs | Up to 198.416 lbs | Up to 198.416 lbs |

| Chamber Size (L × W × H) (inch) | 53” × 24” × 16” | 55” × 30” × 19” | 57” × 30” × 24” | 57” × 30” × 24” | 74” × 38” × 30” | 74” × 38” × 30” |

| Feed Opening (W × H) (inch) | 24” × 16” | 30” × 19” | 30” × 24” | 30” × 24” | 38” × 30” | 38” × 30” |

| Motor Power (hp) | 30 | 40 | 30 | 40 | 50 | 50 |

| Overall Size (inch) | 120″ × 72″ × 60″ | 144″ × 96″ × 72″ | 168″ × 96″ × 96″ | 168″ × 96″ × 96″ | 216″ × 132″ × 120″ | 216″ × 132″ × 120″ |

Hydraulics & Add-On Features:

- Top door spring-loaded unique locking system / hydraulic cylinder locking system

- Bale turn-out/side ejection as optional

- Horizontal cutter on feeding mouth for cutting excess material

- Oil cooler by air/water arrangements

- 180° safety system

- Continuous cycle arrangement with PLC

Special Features:

- Low overall operating cost

- High productivity

- Super high-density bales

- Increased speed of movements

- Lower cycle times through the use of high-pressure pumps

- Low energy consumption

- Easy installation